Start with your breath and guard your every journey.

In modern urban life, air pollution inside the car has become a hidden danger that cannot be ignored. Long-term driving on congested roads leads to the accumulation of exhaust emissions, formaldehyde and other volatile organic compounds (VOCs) released from new car interiors, which may pose a threat to our health. Research data show that long-term exposure to bad air can increase the risk of respiratory diseases.

Therefore, the selection of appropriate air purification device is particularly important. And today we are going to introduce a product that specializes in dealing with these problems- customized HEPA activated carbon automotive air conditioning filter . It can not only effectively block external pollutants from entering the interior of the car, but also greatly reduce the concentration of existing harmful substances, thereby creating a cleaner and more comfortable riding environment.

Revealing HEPA Technology: The Secret Weapon of No Hidden Dust

HEPA(High Efficiency Particulate Air) filtration technology is known in the industry for its super-strong ability to trap fine particles. Compared with traditional fiber or electrostatic dust removal methods, this special material combination can achieve an interception rate of more than 99%, and is especially suitable for the treatment of suspended particles such as PM2.5, which is invisible to the naked eye but extremely destructive.

Imagine that dust will inevitably come in when the windows are ventilated on the highway; and after this filter element is installed, there is no need to worry about similar situations! Because any impurity that tries to break through the barrier successfully will be firmly locked in the grid-like structure arranged in layers and cannot escape.

Activated carbon blessing: a new realm of odor adsorption

If HEPA partially solves the problem of solid particles, then another major protagonist "activated carbon" is responsible for dealing with those invisible killer-like chemical gas components. For example, the taste of the new car mentioned above mainly comes from benzene series and aldehyde decomposition products. The pore structure with large specific surface area carefully selected and processed meets the needs of such problems.

Experiments show that when the sample containing a certain proportion of the above elements is placed in a closed container for a period of time and then the residual value is detected, it is found to be almost below the safety standard line. This is sufficient to prove that the technical means we have adopted have indeed achieved the expected goals and have continued to play a stable role.

The charm of personalized customization

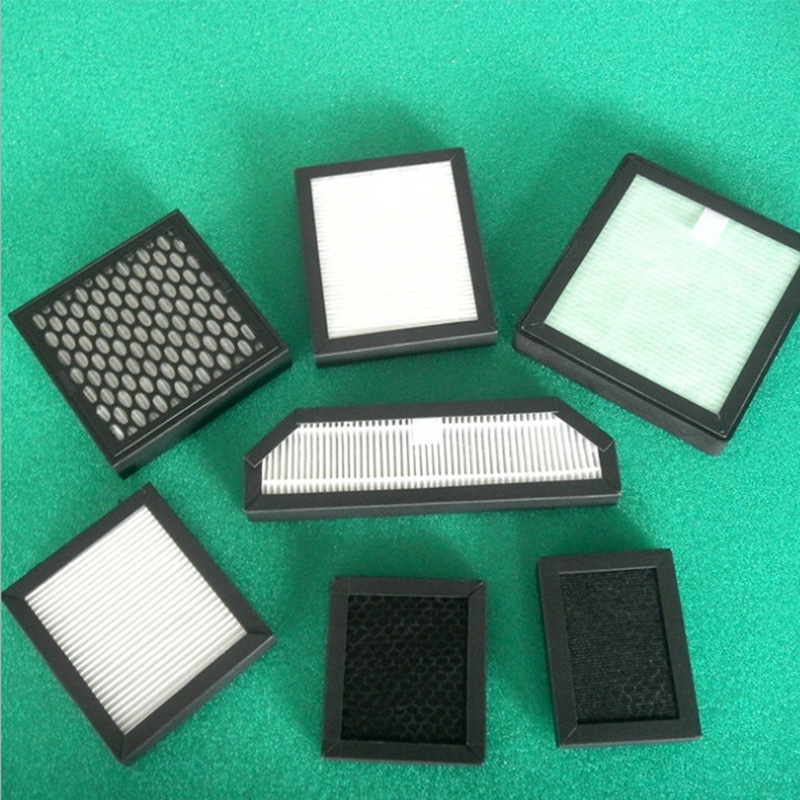

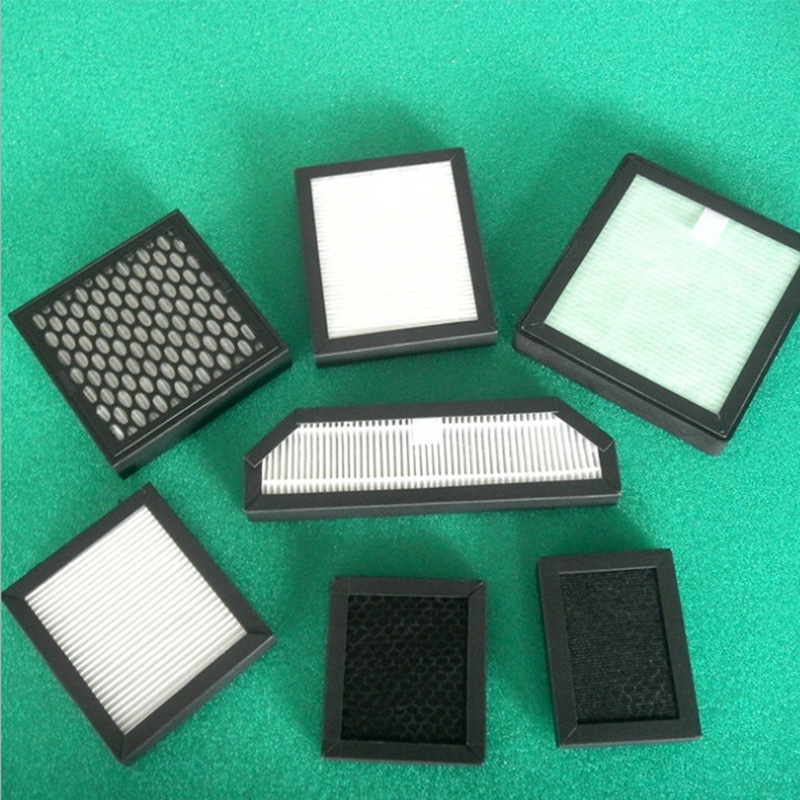

considering the influence of factors such as the variety of mainstream models on the market and the differences in their unique air inlet specifications, in order to ensure that each customer can obtain the best matching effect, this series of products support the operation of on-demand production service mode. In short, professional and technical personnel shall measure and collect the parameters on the spot and then hand them over to the factory to strictly implement the manufacturing process according to the established drawings until the finished product is released.

for example, the special model launched for a german luxury car brand fully reflects this advantage. it uses precision instruments to scan and obtain the original size data, and then uses computer aided design software to simulate and optimize to obtain the final forming scheme to ensure smooth connection and transition of each component without leaving any dead corners and gaps.

Practical application experience: the story behind users' praise

Since its launch, it has received enthusiastic positive comments from many car owners. "I used to feel dry and uncomfortable in my throat, but now it has obviously improved a lot," said a business person who often travels between urban and rural areas. Another housewife said that the baby in the family was prone to cough and runny nose before, but the frequency has been greatly reduced since the equipment was changed... These are tangible examples of change.

of course, in addition to personal subjective feelings, we have also commissioned an independent third-party laboratory to carry out a number of performance verification tests under harsh conditions, including but not limited to high temperature and low temperature cycle impact test, antibacterial and anti-mildew ability evaluation, etc. all the items have successfully passed the customs and obtained the corresponding qualification certificates, adding a confidence guarantee for consumers to purchase.